In the modern industrial environment, digital twin technology and 3D visualization have become essential tools for enhancing production efficiency, asset management, and maintenance engineering. CIDIGITAL's 3D Digital Factory/Plant Operation Platform Solution focuses on providing comprehensive production management, asset management, and maintenance support for the oil and gas industry. By leveraging advanced digital twin technology and real-time data monitoring, this solution not only optimizes plant operations but also improves management efficiency, ensuring the long-term stable operation of assets.

文章源自CIDIGITAL-https://www.cidrg.cn/en/solutions/454.html

文章源自CIDIGITAL-https://www.cidrg.cn/en/solutions/454.html

Solution Overview

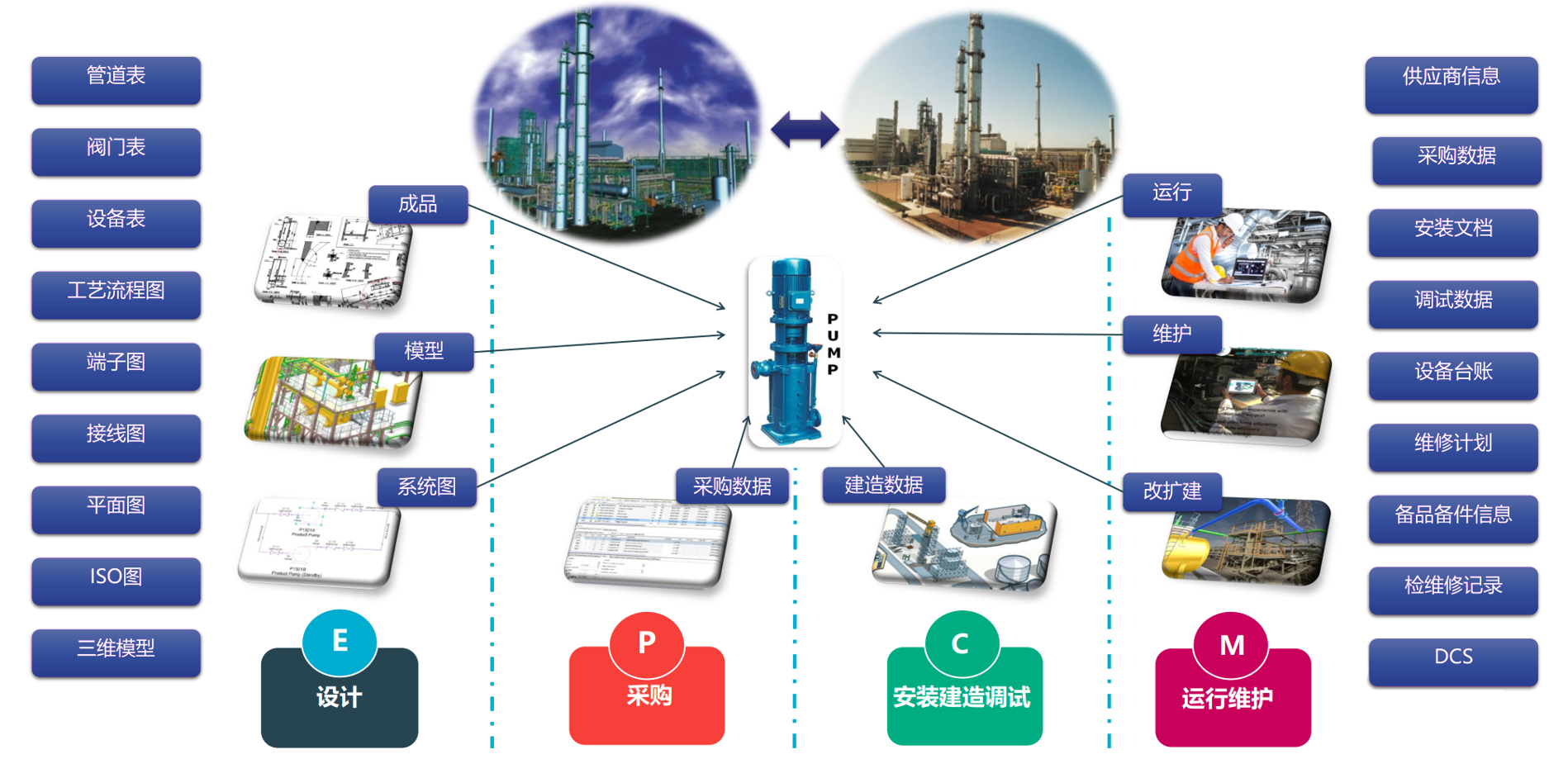

CIDIGITAL's 3D Digital Factory/Digital Plant Operation Platform Solution is designed specifically for the oil and gas industry, enhancing the efficiency of production management, asset management, and maintenance engineering by integrating 3D modeling, digital twin technology, and real-time data monitoring. The core functions of this platform include:文章源自CIDIGITAL-https://www.cidrg.cn/en/solutions/454.html

- 3D Modeling and Digital Twin:

- 3D Modeling: Creating high-precision 3D models of factories and parks, accurately reflecting the physical environment and equipment layout.

- Digital Twin: Integrating real-time data streams into the digital twin, providing a comprehensive visualization of plant operations and equipment health, and offering an immersive visual experience.

- Real-Time Monitoring and Data Integration:

- Real-time data integration into the digital twin supports equipment status monitoring and production process optimization. Users can timely access and analyze data, identify and resolve potential issues, and optimize operations.

- Design Optimization and Planning:

- Design validation and optimization planning are carried out through virtual models, ensuring design accuracy and ease of operation, reducing construction changes, and improving production efficiency.

- Asset Management and Maintenance:

- Real-time data and location support asset management, while predictive maintenance functions help identify potential issues, reduce equipment failures, and extend equipment lifespan.

- Operational Training and Safety Management:

- Operational training and safety drills are conducted using digital twins and virtual reality technology, enhancing employee operational skills and safety awareness.

- Maintenance Engineering Support:

- Comprehensive data support and analysis capabilities are provided to optimize maintenance processes, reduce downtime, and enhance equipment reliability and maintenance efficiency.

文章源自CIDIGITAL-https://www.cidrg.cn/en/solutions/454.html

文章源自CIDIGITAL-https://www.cidrg.cn/en/solutions/454.html

Application of Digital Twin

Digital twin technology supports operational decision-making by creating a virtual model of the plant that reflects the real-time status of physical facilities. It can:文章源自CIDIGITAL-https://www.cidrg.cn/en/solutions/454.html

- Real-Time Monitoring and Analysis: Provide real-time data on equipment status and operations, enabling quick decision-making.

- Predictive Maintenance: Predict equipment failures by analyzing historical data and real-time monitoring, reducing maintenance costs.

- Design and Operation Optimization: Utilize virtual models for design optimization and simulate different operational scenarios to enhance production efficiency and safety.

Support for Operation & Maintenance Engineering

In terms of operation & maintenance engineering, CIDIGITAL's solution offers:文章源自CIDIGITAL-https://www.cidrg.cn/en/solutions/454.html

- Real-Time Data Access: Support field engineers by providing real-time equipment data through the digital twin to optimize maintenance work.

- Fault Diagnosis: Quickly identify the causes of faults through data analysis and develop effective maintenance strategies.

- Optimized Maintenance Processes: Reduce unplanned downtime, increase maintenance efficiency, and extend equipment lifespan.

Solution Advantages

- Enhanced Visualization Experience: 3D modeling and digital twin technology provide realistic, intuitive views, helping users understand complex production facilities.

- Optimized Asset Management: Real-time monitoring and predictive maintenance support efficient asset management, reducing the occurrence of failures.

- Improved Production Efficiency: Design verification and optimization through virtual models improve the efficiency of production processes.

- Increased Safety: Digital twins and virtual reality technology support safety training and risk identification, enhancing overall safety management.

Industry Applications

Applications of this solution in the oil and gas industry include:文章源自CIDIGITAL-https://www.cidrg.cn/en/solutions/454.html

- Production Management: Optimize production processes and enhance production efficiency.

- Asset Maintenance: Achieve efficient asset management through real-time monitoring and predictive maintenance.

- Process Optimization: Utilize digital twins to optimize processes and enhance production safety.

- Maintenance Engineering: Provide comprehensive data support and analysis capabilities to optimize maintenance processes and enhance equipment reliability.

Contact Us

To learn more about CIDIGITAL's 3D Digital Factory/Digital Plant Intergrated Operation Platform Solution, please contact our customer service team. We will provide professional consultation and support to help you achieve digital transformation, enhance production efficiency, and improve management levels.文章源自CIDIGITAL-https://www.cidrg.cn/en/solutions/454.html 文章源自CIDIGITAL-https://www.cidrg.cn/en/solutions/454.html