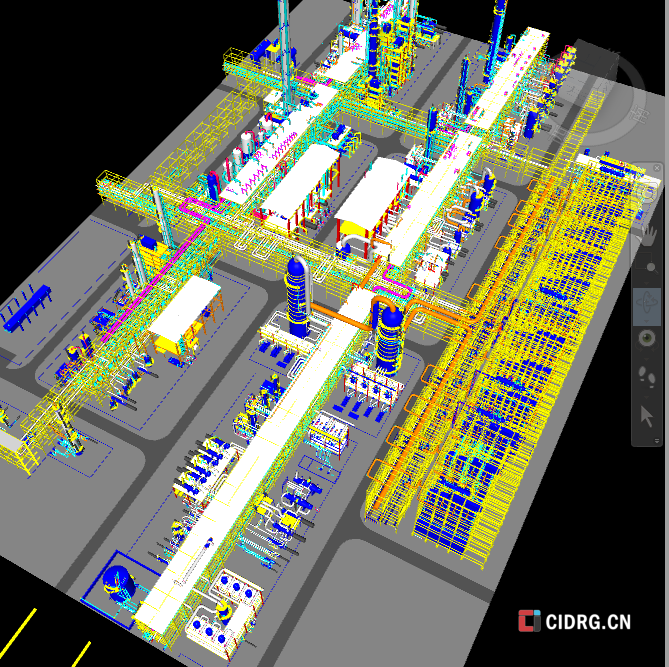

In the chemical industry, the construction of an ethylene plant demands a high level of design precision and efficiency. CIDIGITAL was commissioned by a large petrochemical enterprise to undertake the 3D modeling and engineering design of their new ethylene plant project. The client sought to leverage advanced digital technologies to ensure efficient progress during the design phase and to minimize potential issues during later stages of construction and operation.

文章源自CIDIGITAL-https://www.cidrg.cn/en/cases/494.html

文章源自CIDIGITAL-https://www.cidrg.cn/en/cases/494.html

Challenges and Requirements:文章源自CIDIGITAL-https://www.cidrg.cn/en/cases/494.html

The ethylene plant project involved complex process flows and extensive equipment and piping arrangements. To ensure design accuracy and smooth project execution, the client required the use of industry-leading software for 3D modeling and sought to enhance overall project transparency and collaboration through digital delivery.文章源自CIDIGITAL-https://www.cidrg.cn/en/cases/494.html

Solution:文章源自CIDIGITAL-https://www.cidrg.cn/en/cases/494.html

CIDIGITAL selected the PDS (Plant Design System) software as the core design platform for the project. PDS is a widely recognized 3D design software in the industry, offering robust features and flexible modular design that can support complex process flows and equipment layouts.文章源自CIDIGITAL-https://www.cidrg.cn/en/cases/494.html

During the project implementation, the CIDIGITAL team first engaged in detailed discussions with the client to fully understand their requirements and developed a comprehensive design plan based on the specific needs of the project. The team utilized the advanced capabilities of PDS to create a 3D model that encompassed various aspects such as process flow, equipment layout, and piping design. Throughout the modeling process, CIDIGITAL leveraged PDS’s automation features to significantly improve design efficiency and used the software’s validation tools to ensure the accuracy of the model.文章源自CIDIGITAL-https://www.cidrg.cn/en/cases/494.html

Project Outcomes:文章源自CIDIGITAL-https://www.cidrg.cn/en/cases/494.html

Through the application of PDS software, CIDIGITAL successfully completed the 3D modeling tasks for the ethylene plant project. The digital delivery of the project not only made the design process more transparent but also significantly reduced the risk of changes and rework during the later stages of construction and operation.文章源自CIDIGITAL-https://www.cidrg.cn/en/cases/494.html

The client highly appreciated CIDIGITAL's efficient design and precise delivery. As a result of this collaboration, the client not only advanced the construction of the ethylene plant but also enhanced their own digital design and management capabilities through CIDIGITAL's expertise.文章源自CIDIGITAL-https://www.cidrg.cn/en/cases/494.html

Conclusion:文章源自CIDIGITAL-https://www.cidrg.cn/en/cases/494.html

This project highlights CIDIGITAL's strong 3D modeling capabilities and professional project management experience in large-scale chemical projects. By adopting PDS software, CIDIGITAL not only met the client's high-standard design requirements but also laid a solid digital foundation for the client’s future projects.